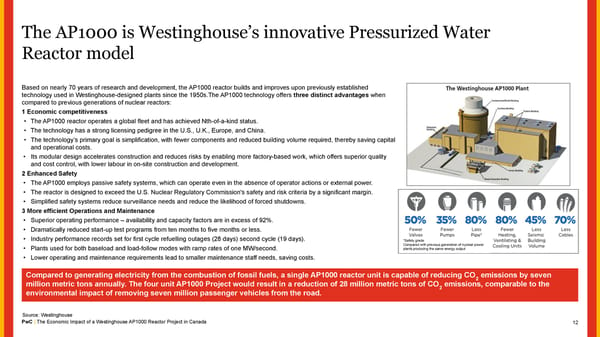

The AP1000 is Westinghouse’s innovative Pressurized Water Reactor model Based on nearly 70 years of research and development, the AP1000 reactor builds and improves upon previously established technology used in Westinghouse-designed plants since the 1950s.The AP1000 technology offers three distinct advantages when compared to previous generations of nuclear reactors: 1 Economic competitiveness • The AP1000 reactor operates a global fleet and has achieved Nth-of-a-kind status. • The technology has a strong licensing pedigree in the U.S., U.K., Europe, and China. • The technology’s primary goal is simplification, with fewer components and reduced building volume required, thereby saving capital and operational costs. • Its modular design accelerates construction and reduces risks by enabling more factory-based work, which offers superior quality and cost control, with lower labour in on-site construction and development. 2 Enhanced Safety • The AP1000 employs passive safety systems, which can operate even in the absence of operator actions or external power. • The reactor is designed to exceed the U.S. Nuclear Regulatory Commission's safety and risk criteria by a significant margin. • Simplified safety systems reduce surveillance needs and reduce the likelihood of forced shutdowns. 3 More efficient Operations and Maintenance • Superior operating performance – availability and capacity factors are in excess of 92%. • Dramatically reduced start-up test programs from ten months to five months or less. • Industry performance records set for first cycle refuelling outages (28 days) second cycle (19 days). *Safety grade. Compared with previous generation of nuclear power plants producing the same energy output • Plants used for both baseload and load-follow modes with ramp rates of one MW/second. • Lower operating and maintenance requirements lead to smaller maintenance staff needs, saving costs. Compared to generating electricity from the combustion of fossil fuels, a single AP1000 reactor unit is capable of reducing CO emissions by seven 2 million metric tons annually. The four unit AP1000 Project would result in a reduction of 28 million metric tons of CO emissions, comparable to the 2 environmental impact of removing seven million passenger vehicles from the road. Source: Westinghouse PwC | The Economic Impact of a Westinghouse AP1000 Reactor Project in Canada 12

The Economic Impact of a Westinghouse AP1000 Reactor Project in Canada Page 11 Page 13

The Economic Impact of a Westinghouse AP1000 Reactor Project in Canada Page 11 Page 13